Filter

344 products

Sort by:

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

-

Vendor: ChainHeadWaySBS Interchangeable Boring Cutter for Versatile Precision Machining

● DeliverableInquiry18 variantsFeature Applicable for BSA BSB rough boring cutter. SBS is suitable for fine processing and medium cutting processing.

● DeliverableInquiry18 variantsFeature Applicable for BSA BSB rough boring cutter. SBS is suitable for fine processing and medium cutting processing. -

Vendor: ChainHeadWayBrazed Boring Cutter for Enhanced Machining Efficiency

● DeliverableInquiry15 variantsK Cast Iron, aluminium alloy P Alloy Steels Before the purchase please indicate K or P

● DeliverableInquiry15 variantsK Cast Iron, aluminium alloy P Alloy Steels Before the purchase please indicate K or P -

Vendor: ChainHeadWayStraight Boring Bar - Accurate Hole Enlargement and Finishing

● DeliverableInquiry6 variants

● DeliverableInquiry6 variants -

Vendor: ChainHeadWayBT 45° Square Cutter Boring Bar Holder – High-Precision Tool Holder for Boring Applications

● DeliverableInquiry23 variantsFeature Selects the foursquare carbide tipped cutter or supplementalcutting tool. Exclusively for boring blind hole.

● DeliverableInquiry23 variantsFeature Selects the foursquare carbide tipped cutter or supplementalcutting tool. Exclusively for boring blind hole. -

Vendor: ChainHeadWayBT 90° Square Cutter Boring Bar Holder – High-Precision Tool Holder for Boring Applications

● DeliverableInquiry18 variantsFeature Suitable for the uneven hole & raw parts with rough surface. Selects the foursquare carbide tipped cutter or supplementalcutting tool. Exclusively for boring through hole.

● DeliverableInquiry18 variantsFeature Suitable for the uneven hole & raw parts with rough surface. Selects the foursquare carbide tipped cutter or supplementalcutting tool. Exclusively for boring through hole. -

Vendor: ChainHeadWaySCK Straight Boring Shank – Precision Machined Tool Holder for Boring Applications

● DeliverableInquiry11 variants

● DeliverableInquiry11 variants -

Vendor: ChainHeadWaySCK Straight Carbide Boring Shank – High-Precision, Wear-Resistant Tool Holder

● DeliverableInquiry9 variants

● DeliverableInquiry9 variants -

Vendor: ChainHeadWayCarbide Arbor for SCK Extension – High-Precision, Durable Cutting Tool Adapter

● DeliverableInquiry2 variants

● DeliverableInquiry2 variants -

Feature For CBH100DP~CBH200DP /CK7R

-

-

-

-

Feature Internal tolerance is H6. The tool holder with through coolant design is better for water to get through vibration resistance.

-

-

Vendor: ChainHeadWayHSK40A-100A/MCK Boring Head Shank(For Type A)

● DeliverableInquiry29 variants

● DeliverableInquiry29 variants -

-

Feature Internal tolerance is H6. The tool holder with through coolant design is better for water to get throughvibration resistance Sharing and mutual tolerance in most of the"CK" series. Side of the locking screw and keyway was 90 degrees, to ensure that therelative position...

-

Feature Internal tolerance is H6. The tool holder with through coolant design is better for water to get throughvibration resistance Sharing and mutual tolerance in most of the"CK" series. Side of the locking screw and keyway was 90 degrees, to ensure that therelative position...

-

-

Feature Internal tolerance is H6. The tool holder with through coolant design is better for water to get through vibration resistance Compatible tolerance in most of the "CK" series. Side of the locking screw and keyway was 90 degrees, to ensure that therelative position of...

-

-

-

Feature Both inserts operate with a fine adjustment and simultaneous movenment, suitable for big feeding (F) cutting.

-

-

-

Vendor: ChainHeadWaySMB Super Micron Exchangeable Finish Boring Head

● DeliverableInquiry7 variantsFeature For finish boring. Micro-adjustment unit : each unit is 0.01 mm. The insert seat is designed to have a coolant holes at sides, which can remove the metal chips effectively and raise the manufacturing effect. The insert seat has an exchangeable design and...

● DeliverableInquiry7 variantsFeature For finish boring. Micro-adjustment unit : each unit is 0.01 mm. The insert seat is designed to have a coolant holes at sides, which can remove the metal chips effectively and raise the manufacturing effect. The insert seat has an exchangeable design and... -

Vendor: BIGtoolsCNC Eccentric Tool Holder, Precision Boring Holder, Small Reverse Boring Tool, Reverse Scraping, Customized Non-standard.

● Deliverable

● Deliverable- $51.43

- $51.43

- Unit price

- / per

1 variants -

Vendor: NTFor Back Chamfering with Axially Adjustable Machines such as Machining Center and Milling Machine

● DeliverableInquiry15 variantsommercially available inserts can be used. Great for cost saving.

● DeliverableInquiry15 variantsommercially available inserts can be used. Great for cost saving. -

Vendor: BIGtoolsBack Pull Countersink Tool Holder, Back Pull Cutter, CNC M16.

● Deliverable

● Deliverable- From $34.29

- From $34.29

- Unit price

- / per

22 variantsMaterial: Nickel-chromium alloy steelCoating: Coated Eccentric reverse pull counterbore • Reverse pull countersink solves machining challenges, no need to flip the part for counterbore processing • Significantly improves machining efficiency -

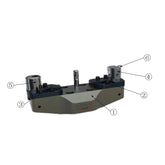

Vendor: BIG DAISHOWASimplest Mechanism Achieves Automatic Back Spot Facing in Machining Centers

● DeliverableInquiry24 variantsOnlv forward/reverse rotation of the machine spindle makes back spot facing and back chamfering possible. Abundant varieties and unigue opening/closing method make it ideal for cast iron and aluminum machining.

● DeliverableInquiry24 variantsOnlv forward/reverse rotation of the machine spindle makes back spot facing and back chamfering possible. Abundant varieties and unigue opening/closing method make it ideal for cast iron and aluminum machining.