Filter

Alphabetically, A-Z

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

Sort

6215 products

Sort by:

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

-

LUE built-in internal support gas and hydraulic chucks are assembled with PUE internal support chucks and LY vertical cylinders; Chucks fixed on drilling machines, milling machines or machining centers are easy to use, exquisitely designed, and simple to install; LUE built-in oblique column gas...

-

Easy to install on fixed cylinders such as drilling machines, milling machines, tapping machines and machining centers. Can be operated by air pressure or oil pressure.

-

-

Vendor: BIG DAISHOWAM2 - M20 Mega Synchro Tapping Holder PAT Large Diameter Tap MGT36

● DeliverableInquiry7 variants

● DeliverableInquiry7 variants -

-

-

KEY ADVANTAGES Extremely fast conversion without detachment of the basic clamping device [1-2min.] Large clamping range and vibration dampening due to vulcanized clamping elements Standard segmented clamping bushings and workpiece endstops for machine to size available

-

KEY ADVANTAGES Extremely fast conversion without detachment of the basic clamping device [1-2min.] Large clamping range and vibration dampening due to vulcanized clamping elements Standard segmented clamping bushings and workpiece endstops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES 1. Extremely high clamping force even at the smallest clamping 2. Clamping range ∅ 8-200mm 3. Large clamping range and vibration dampening due to vulcanized clamping elements 4. Standard segmented clamping bushings and workpiece end-stops for machine to size available

-

KEY ADVANTAGES Ideal for automated clamping Angular contour requires less space Multiple clamping made possible in the smallest space Ideal for 5-sided machining Clamping is possible with workpiece end-stop or front end-stop Adaptation devices possible

-

KEY ADVANTAGES Ideal for automated clamping Angular contour requires less space Multiple clamping made possible in the smallest space Ideal for 5-sided machining Clamping is possible with workpiece end-stop or front end-stop Adaptation devices possible

-

KEY ADVANTAGES Ideal for automated clamping Angular contour requires less space Multiple clamping made possible in the smallest space Ideal for 5-sided machining Clamping is possible with workpiece end-stop or front end-stop Adaptation devices possible

-

KEY ADVANTAGES Mandrels can be used on machine center Ms dock rotating for lathes without clamping cylinde Manual/hydraulic mandrel actuation Ideal for 5-sided machining Clamping range ∅8-200mm

-

Vendor: BIG DAISHOWAManual Tool Change Type Air Turbine Spindle HSK-A 63/100

● DeliverableInquiry4 variants

● DeliverableInquiry4 variants -

-

-

Features: General level Pull stud Material: 40Cr. Head hardness: 46-50HRC. Thread hardness is a little low; 35$5HRC, (Protect shank thread, core hardness can resist hit). Accuracy: 0.02. High-precision Hard Pull stud Material: 20CrMnTi. Head hardness: 55-58HRC. Thread hardness is a little low; 35+5HRC, (Protect...

-

Vendor: ChainHeadWayMBH Finish Boring Head – High-Precision Adjustable Tool

● DeliverableInquiry11 variantsFeature MBH Finish Boring Head is suitable for fine boring with working range from Ø16 to Ø200mm diameter. Every division for adjustment is 0.01mm diameter. High precision lead screw and nut have been heat treated and hardened, with high durability. Built-in coolant nozzle is easy for...

● DeliverableInquiry11 variantsFeature MBH Finish Boring Head is suitable for fine boring with working range from Ø16 to Ø200mm diameter. Every division for adjustment is 0.01mm diameter. High precision lead screw and nut have been heat treated and hardened, with high durability. Built-in coolant nozzle is easy for... -

Vendor: ChainHeadWayMBH Large Diameter Finish Boring Head – Heavy-Duty CNC Milling & Lathe Tool

● DeliverableInquiry6 variantsFeature MBH Finish Boring Head is suitable for fine boring with working range from Ø200 to Ø1250mm diameter. Every division for adjustment is 0.01mm diameter. High precision lead screw and nut have been heat treated and hardened, with high durability. Insert holder is with two-face support,...

● DeliverableInquiry6 variantsFeature MBH Finish Boring Head is suitable for fine boring with working range from Ø200 to Ø1250mm diameter. Every division for adjustment is 0.01mm diameter. High precision lead screw and nut have been heat treated and hardened, with high durability. Insert holder is with two-face support,... -

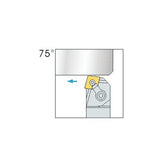

Vendor: BIGtoolsMCBN R/L Turning tool holder A M

● Deliverable

● Deliverable- From $13.57

- From $13.57

- Unit price

- / per

10 variants

Related categories

3 Flute Carbide Drills

BIG DAISHOWA

Carbide Drill Bits

Coolant

Damping Tools

Deburring Tools

Digimatic

End Mills for High Temp Alloys

End Mills for High-Hardness Materials

Endmills for Stainless Steels

External Coolant

Extrnal

Finishing End Mills

For Copper and Aluminum Alloys

High Efficiency Machining

High Performance Endmill for Composite

High Speed Machining of Graphite

High-Feed Carbide End Mills

HSS Roughers

Insert

Internal

Internal Coolant

ISCAR

Large Diameter Boring

Mega Chuck

Micro Deep End Mills

Modular Drill

PB Swiss Tools

PCD Drill

PCD End Mills

Rough Boring

Roughing End Mills

Ruby

Shallow Hole Drill

Small Parts Machining

Solid End Mills for Dental

Swiss Type Lathe

TaeguTec

Tungsten carbide

Without Coolant

ZCCT